Our marking technology expansion systems allow the simple and quick expansion of our marking devices for partial to full automatization. Series marking is simplified and the identical marking ensured on all parts. The various prism supports, which we are also happy to tailor individually to your parts to be marked, simplify the insertion and positioning of the parts to be marked. This increases process reliability and makes marking large quantities child's play.

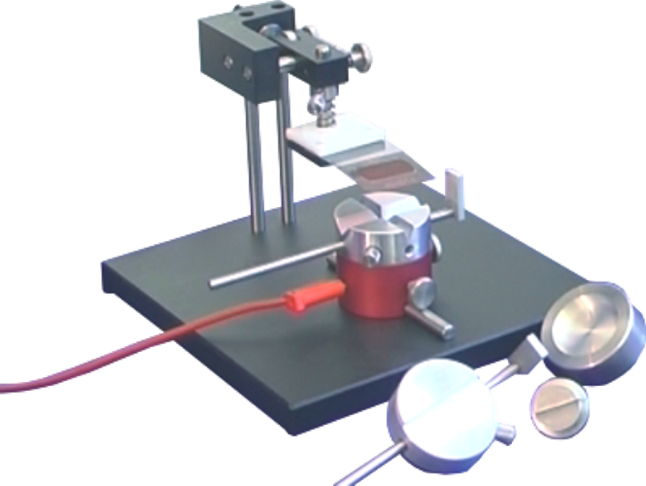

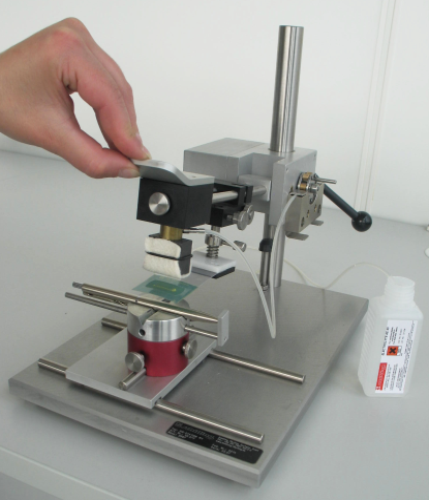

Work Holding Unit L1

Third Hand

With the work-holding unit L1, you gain a “third hand” that allows you to mark smaller series comfortably. The L1 can be combined with all control devices and can therefore be used very flexibly. As standard, with work-holding unit L1 you receive a neutral, flat marking table. Other marking tables, such as for tweezers or scissors, are also available. It is also no problem to order a customized marking table from us that our production team is happy to adapt to your workpiece to be marked. Thus, precise marking of your parts is made easier for you and the marking process is standardized.

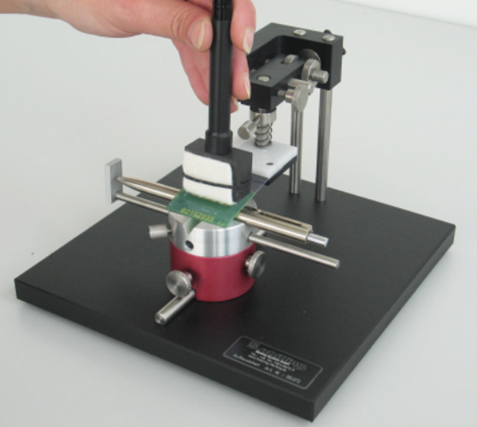

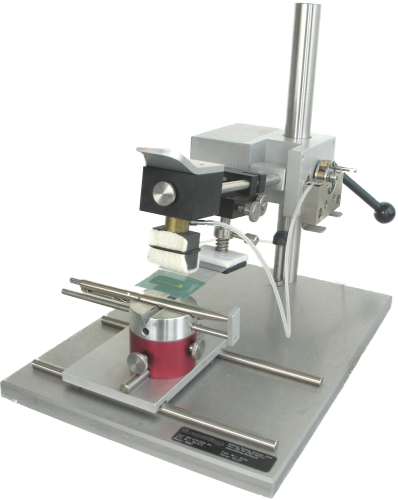

Etch-Station M1

- For marking small to medium-sized series

- Can be combined with all Schilling control units

- Automatic supply of electrolyte with every stroke

Easy. More. Marking.

With Etch-Station M1, small and medium-sized series can be marked conveniently and quickly. The M1 can be combined with all control devices. You are thus very flexible with regard to the expansion of your Schilling marking devices. Due to the effective partial automatization and the automatic electrolyte feed in every marking, you always receive consistent markings, with simple operation at the same time. No matter which workpiece you want to mark – with the stencil holder fine adjustment it is possible always to tailor the marking station precisely to your part to be marked. Due to its height adjustability up to 160 mm, marking high parts also presents no problem for the M1. Marking tables, available in various forms, enable simple insertion of the parts, which increases process reliability in marking. We would also be happy to produce your own customized marking table in accordance with your specifications.

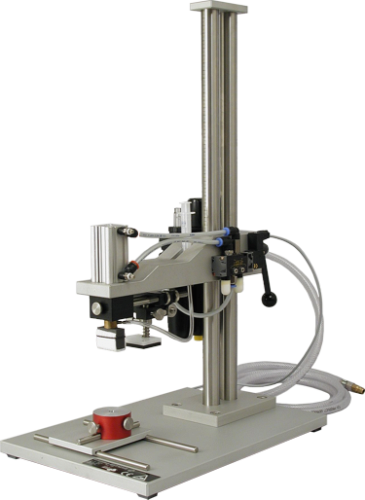

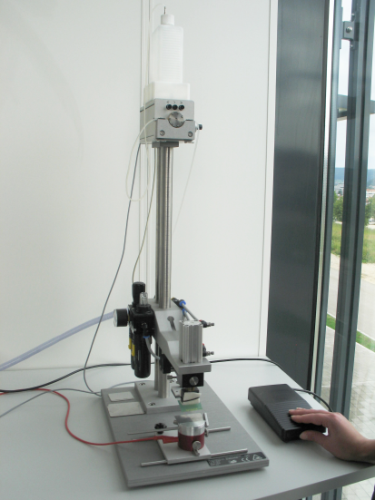

Pneumatic Work Holder

- For medium-sized and large series

- For control units Signomat S100, S2 und S2000

- Constant contact pressure

A Class Faster

Our semi-automated pneumatic work holder is suitable for marking medium-sized and large series. It can be connected to control devices S100, S2 and S2000 and can be operated with a foot switch. Work holders facilitate the constant positioning of workpieces and thus increase process reliability. We would be happy to produce customized work holders for your particular parts. The optionally available electrolyte pump ensures a constant electrolyte feed, which ensures that the marking result always stays the same.

Extension Systems Contact Form